Urethane Casting

Cast Urethane Service |

At Brecher Manufacturing, our urethane casting services are best suited for prototyping high-quality parts with a wide variety of properties to suit design complexities.

The cast urethane process is fast and scalable for the production of 20 to 100 units for applications where you are still not ready for a big batch with Plastic Injection Molding.

Understanding the Urethane Casting Process

Urethane casting is a rapid prototyping technique where silicone and urethane (polyurethane) molds are used to form high-quality production-grade plastic parts.

Urethane casting (cast urethane), silicone molding, RTV molding, also known as RTV Tooling, urethane casting is an excellent production procedure used in rapid prototyping and batch manufacturing of parts at lower costs and faster turnaround times.

With urethane casting, molding is typically done with silicone.

The mold is created using a master pattern by either CNC machining or 3D printing, using liquid silicone to provide high-precision simulation of finished products. This procedure is best suited for prototyping and low-volume production of parts for testing, market display, trade shows/showcasing, or pilot testing.

Our urethane casting services are best suited for prototyping high-quality parts for low-volume applications.

Urethane Casting is a great Injection Molding alternative and a great tool in Rapid Prototyping for when the volume is too low for highly costly Mold/Tooling, or when you are constantly improving a product.

Why Brecher Manufacturing for Urethane Casting?

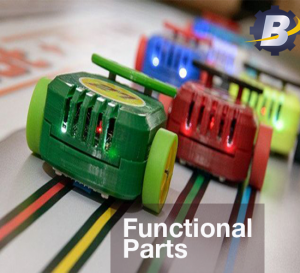

High precision Cast Urethane

Urethane casting is used to simulate a 3D printed pattern or a CNC Machined Part.

Urethane casting tools are made of silicone rubber, which molds and gives precise details, texture, and uniform finishes to suit the final applications.

Urethane casting tools are made of silicone rubber, which molds and gives precise details, texture, and uniform finishes to suit the final applications.

Work with us to accelerate your product development cycles and move from prototype to functional test parts in as little as 3 weeks!

At Brecher Manufacturing, we provide competitive production alternatives that give our customers the ability to test finished products without investing in hard, expensive tooling. With great accuracy and consistency, urethane castings provide many advantages in product development cycles. Here are some key benefits as to why ours is the ideal process:

Quick Turnaround

We satisfy customers looking for high-quality, low-volume production parts by giving our customers the advantage of having their products in reasonable quantities for functional testing long before hard machining is completed. We have improved our urethane casting process to work in a wide variety of industries.

Competitive Pricing

We provide urethane casting as a suitable alternative in situations where the cost of hard tooling restricts production.

Request a Quote

Also, follow us on Linkedin for more information about what we do.

Urethane Casting Services Near or Delivered to YOU

If you don’t find your city give us a call, we have customers all over the US, in Mexico & Canada, and have shipped to Europe as well.

San Diego

California

Orange

California

Yorba Linda

California

Oakland

California

Berkeley

California

Burlingame

California

Palo Alto

California

Fremont

California

Mountain View

California

Sunnyvale

California

Santa Clara

California

San Jose

California

Stockton

California

San Francisco

California

Los Angeles

California

Riverside

California

Rancho Cucamonga

California

Redlands

California

Ontario

California

Fontana

California

Glendale

California

Upland

California

City of Commerce

California

Orange County

California

Los Angeles County

California

San Diego County

California

Inland Empire

California

Anaheim

California

Irvine

California

Oceanside

California

Carlsbad

California

San Antonio

Texas

Chandler

Arizona

Phoenix

Arizona

Tijuana

Mexico

Ensenada

Mexico

Mexicali

Mexico

Tecate

Mexico

Monterrey

Mexico

Queretaro

Mexico

Puebla

Mexico